SensorX increase your production by approx. 20%

- Results are visible within the first week after installation.

- In this simple way, we will measure the performance of machines, employees and processes.

- We will reveal weaknesses in your production.

- Return of investments within a few weeks

Umíme osadit stroje těchto značek

How it works

01

Placement of sensors

We will equip the machine with our sensors, which we will select according to your machines. We need just access to electricity.

Easy and non-invasive installation of the sensors.

02

From paper to tablet

Data from sensors, we will add additional data from employees. The employee will complete the reasons for the shutdowns. People will move from paper to a more modern version of the record.

03

Weekly data collection

We collect data into our PortalX platform for a week. You can connect to it via the web interface or from any mobile platform. We can connect the data to your internal system (SAP, Helios, Abra, etc.)

04

Unproductive production

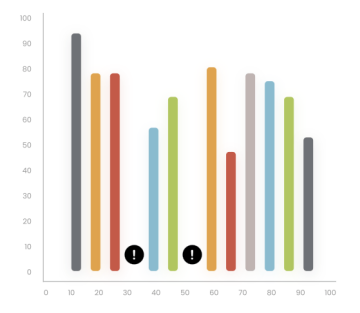

We use Power BI or Excel for better data visualization. Here we are able to show you where there are deficiencies in your production and possibly how much money you are losing.

05

Optimization of production

Thanks to data, we are able to help you optimize production. The investment in SensorX returns to our customers within weeks.

Do you want to know more, so write to us?

What is SensorX

- SensorX is a sophisticated system that can collect data from machines and your employees

- We can install SensorX on machines by non-invasive way. We usually put sensors on moving elements or power cables.

- Thanks to the available application, you can get data from your employees very easy

- Your data is protected. We encrypt and anonymize data.

The advantage for you is that you can try SensorX for a weekly test including a consultation

Data visualization and interpretation

- No rewriting data on paper and back to the PC. Your data will be recorded immediately

- Higher quality control of the production process

- You can measure scrap and find out why it happens

- Eliminate downtime of individual machines

- You can accurately motivate employees for their performance because the data is accurate

- You can calculate the profitability of individual orders and then decide whether to accept the order

- The data can be uses for sales department for better pricing of orders

We visualize data in Power BI, Excel, PortalX